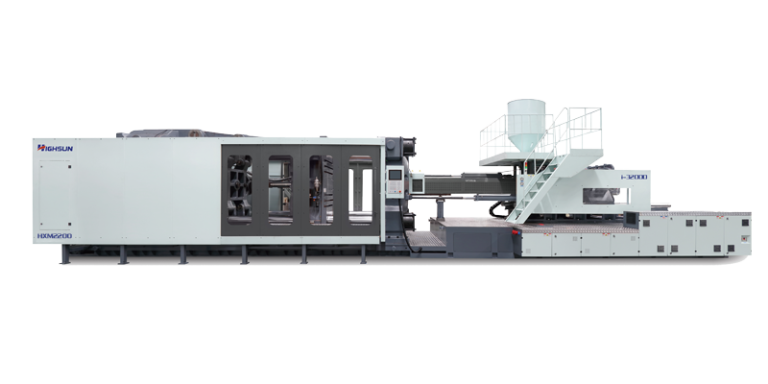

HXM2200: HXM servo injection molding machine

High quality features

The “new breakthrough” of the hydraulic injection molding machine has realized “pressure valve ring control” and “energy supply and demand matching”, professional shape future !

Pressure valve ring control: The actual pressure is compared with the set pressure in real time and corrected until the actual pressure is equal to the set pressure.

Matching energy supply and demand: How much energy does the injection molding machine do, how much energy the power system provides, and very little energy loss.

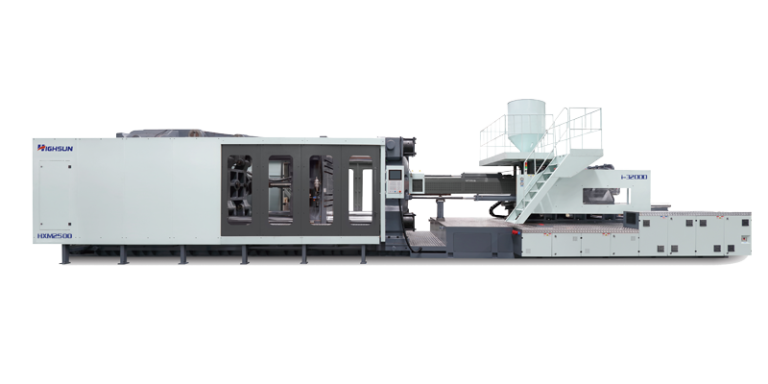

HXM2500: HXM servo injection molding machine

High quality features

The “new breakthrough” of the hydraulic injection molding machine has realized “pressure valve ring control” and “energy supply and demand matching”, professional shape future !

Pressure valve ring control: The actual pressure is compared with the set pressure in real time and corrected until the actual pressure is equal to the set pressure.

Matching energy supply and demand: How much energy does the injection molding machine do, how much energy the power system provides, and very little energy loss.

HXM158-PET: PET-preform injection molding machine

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM218-PET: PET-preform injection molding machine

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM258-PET: PET-preform injection molding machine

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM298-PET: PET-preform injection molding machine

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM330-PET: PET-preform injection molding

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM470-PET: PET-preform injection molding

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM530-PET: PET-preform injection molding

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM630-PET: PET-preform injection molding

1.Specially designed screw and high-torque melt motor are used to facilitate the plasticization and molding of PET raw materials;

2.Equipped with an ejection device sufficient to meet the production of PET products;

3.The high-power motor-pump system makes the cycle period shorter and increases the production efficiency;

HXM218-PVC: PVC injection molding machine

HIGHSUN PVC fitting machine, clamping force:218-1100T

1.Adopt the special design of screw & barrel for PVC material, install the air fan for cooling barrel to avoid the material overheating and coking;

2. Increased bigger grade oil motor to facilitate PVC raw material plasticizing and molding;

3.Extended width of security door for making PVC fitting mould with better installation, to suit PVC fitting molds (core puller cylinder) installation convenience;

4.Supply with special technical solution for PVC injection, not only modify the screw & barrel like others, but also the special solution with complete hydraulic system and injection unit.