|

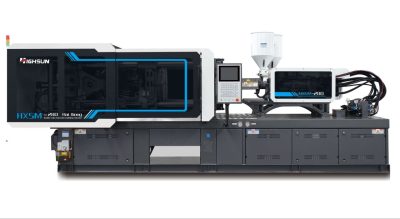

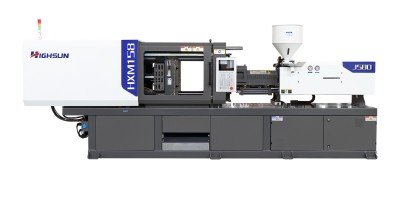

HXYD260 |

||||||||||

| Clamping Unit واحد گیره | ||||||||||

| Clamping force نیروي گیره |

kN |

2600 |

||||||||

| Moving mould-plate stroke کورس بازشو گیره |

mm |

530 |

||||||||

| Max.Mould height بیشترین ارتفاع قالب |

mm |

600 |

||||||||

| Min.Mould height کمترین ارتفاع قالب |

mm |

230 |

||||||||

| Space between tie-bars فاصله بین تایبارها |

mm |

610X560 |

||||||||

| Hydraulic ejector force نیروي پران |

kN |

87 |

||||||||

| Hydraulic ejector stroke کورس پران |

mm |

150 |

||||||||

| Ejector number تعداد میل پران |

n |

13 |

||||||||

|

|

||||||||||

| Injection Unit |

i650 |

i900 |

i1000 |

|||||||

| Screw diameter قطر ماردون |

mm |

40 |

45 |

50 |

45 |

50 |

55 |

50 |

55 |

60 |

| Screw LD ratio نسبت D/L ماردون |

LD |

22 |

20 |

20 |

22.2 |

20 |

20 |

22 |

20 |

20 |

| lnjection capacity in theory حجم تزریق |

Cm³ |

263 |

334 |

412 |

381 |

471 |

570 |

471 |

570 |

678 |

| Injection weight(PS) وزن تزریق بر مبناي پلی استایرن |

g |

240 |

303 |

375 |

347 |

428 |

518 |

428 |

518 |

617 |

| Injection pressure فشار تزریق |

bar |

2531 |

2000 |

1620 |

2469 |

2000 |

1653 |

2178 |

1800 |

1513 |

| Injection velocity نرخ تزریق |

mm/s |

350 |

350 |

350 |

||||||

| Plasticizing capacity |

g/s |

30 |

42 |

50 |

42 |

50 |

60 |

50 |

60 |

75 |

| Screw speed سرعت ماردون |

rpm |

400 |

400 |

400 |

||||||

|

|

|

|

|

|||||||

| Other سایر |

|

|

||||||||

| Pump pressure حداکثر فشار پمپ |

MPa |

17.5 |

||||||||

| Motor/Driving power توان موتور پمپ |

kW |

37(注)+23(熔)+30(油) |

37(注)+23(熔)+30(油) |

37(注)+23(熔)+30(油) |

||||||

| Heating capacity توان المنت ها |

kW |

13.55 |

13.55 |

16.83 |

||||||

| Machine dimension ابعاد دستگاه |

m |

6.17×1.56×1.82 |

6.37×1.56×1.92 |

6.57×1.56×2.12 |

||||||

| Machine weight وزن دستگاه |

t |

9.7 |

10 |

10.2 |

||||||

| oil tank capacity ظرفیت مخزن روغن |

L |

412 |

||||||||

HXYD-260: HXYD hybrid injection molding machine

HXYD Series – Hybrid Injection Molding Machine is a new solution scheme for high-end packaging industry, high-end daily necessities industry and medical supply industry, which is based on full-electric machine(Injection rate: 500mm/s; production was started in 2009) and high-speed machine (production was started in 2012). It is combined with the clamping parts of high-speed machine and injection parts of full-electric machine, taking into account the demand of energy saving and environmental protection. It meets the requirement of large clamping force and high performance injection unit for this kind of product. (Mould Open&Charge Simultaneously.)

توضیحات